Links

Visit DoItYourself.com - The Leading Home Improvement and Remodeling Website Featuring the Internet's Largest Hardware Superstore

Click my Brick Directory

123 Web Directoty

Directory, direct links

Are You INTO TECHnology?

Find Top Links - Link Directory

Webmaster Earth Directory

Kasan Web Directory

Woodworkers Shop Tools Hardware and Supplies - We've got the best brand tools in the business. Delta, Jet, DeWalt, Bosch, and Porter Cable.

Top cordless drill makers: DeWALT

You buy a machine and what you really get is satisfaction, entire satisfaction.

- R. E. DeWALT

The original company was started in 1924 by Raymond E. DeWalt, the inventor of the radial arm saw. The company grew quickly and was reorganized in 1947, manufacturing radial arm saws and other stationary woodworking machines. After buying the company in 1949, American Machine & Foundry Co. Inc. sold it to Black & Decker in 1960. Black & Decker divested itself of the radial arm saw manufacturing branch in 1989, selling it to two executives. Radial arm saws that use the original DeWalt design can still be obtained from the Original Saw Co.

In 1992, Black & Decker started a major effort to rebrand its professional quality and high-end power tools to DeWalt.

In 1994, DeWalt took over the German high end wood working power tool producer ELU. DeWalt enlarged their assortment of cordless tools and other tools using ELU's technology. DeWalt has maintained this focus on high-end branding, and consistenly is identified as the most preferred brand of commercial tools in recent surveys of commercial contractors

Today the DeWALT Power Tools line consists of over 200 electric power tools and over 800 accessories including: drills and hammer drills; screwdrivers; circular, chop, miter, table, reciprocating, and jig saws; planers; impact wrenches; die, angle, and bench grinders; shears; nibblers; sanders; laminate trimmers; routers, and plate joiners.

You can visit official DeWALT site

Information source Wikipedia, the free encyclopedia

Post sponsored by Cheap Dewalt Power Drills - Find the very best cheap Dewalt Power Drills on sale at discount prices.

Related posts:

Maintaining cordless NiMH/NiCad(NiCd) batteries

Cordless drill do not need cord because the drill use energy from the battery. The battery is a very important part of cordless drill and cordless tools in general. Exist different types of batteries for cordless tools, and each type has its own features in maintenance and use. The main battery types are nickel-cadmium (NiCad[1], NiCd) batteries, Nickel metal hydride (NiMH) batteries and Lithium-ion batteries (sometimes abbreviated Li-ion batteries). NiCd and NiMH batteries is used often in cordless tools so in this post I want to give you information about using and charging NiCd and NiMH batteries. In internet you can find a lot of information about maintaining NiMH/NiCad batteries and in this post I will try to combine information from different sources in such manner that you will can see the overall picture of how to use and how to charge NiMH/NiCd batteries.

NiCd battery

The nickel-cadmium or ‘NiCd’ battery is the most popular type of rechargeable battery in the world today, despite the development of new types offering higher energy storage density. That’s no doubt because the NiCad combines relatively low cost with fairly high storage density, the ability to deliver very high load currents on demand and the ability to be recharged very quickly.

The basic nickel-cadmium battery was invented in 1899 by Waldmar Jugner, but the modern sealed type dates from about 1947.

NiCds battery are composed of an anode (positive plate of nickel oxide/hydroxide), a cathode (negative plate of cadmium metal with cadmium hydroxide) with two layers of porous separator material impregnated with electrolyte of potassium hydroxide ('‘caustic potash’'). The sandwich is then rolled up and packaged in a nickel-plated steel can.

NiCd batteries approximatively have an energy storage density of between 40 and 60 watt-hours per kilogram.

The principal advantages of NiCd over other rechargeable types is lower weight for a given quantity of stored energy, good charging efficiency, low internal resistance, thus can achieve a higher maximum discharge rate (which can be important for applications such as power tools), and non-critical charging conditions.

The well-known drawback of NiCds is the "Memory effect’."

It occurs by the formation of crystals(Cadmium crystals) inside the battery. These crystals are hard to dissolve and the ones responsible for the “memory effect”. So the trick to avoid the “memory effect” is to avoid the formation of those crystals inside the battery. This is typically accomplished by recharging the battery only when it is discharged and not when it is partially discharged. Careful recharging using the correct techniques can also be used to reverse crystal growth.

Remember, NiCd cannot be fully discharged or they will be damaged. Fully discharged usually means having a voltage below 1 V per cell (NiCd batteries are usually formed by grouping several 1.2 V cells; typical NiCd batteries are 3.6 V packs using three 1.2 V cells).

So the “trick” that is recommended by many people to solve “memory effect” by fully discharging NiCd batteries by shorting them (or any other sort of “quick discharge”) does in fact more damage than good to the batteries, even though several people claim that they can recover NiCd batteries with “memory effect” by doing this.

Also, high temperatures help the crystals to be formed. Heat is the enemy of batteries. A NiCd stored, used, or charged under high temperature conditions will die an early death. Heat causes the separator to weaken and greatly accelerates changes in the plate material.

NiCd charging & chargers

NiCd batteries need to be recharged with a reasonable amount of care, largely because they can be damaged by overcharging. The demand for rapid charging has lead to a great increase in overcharging abuse. Most all NiCd cells can be rapid charged. The trick is to stop charging when it is fully charged. The so called "rapid charge" type of cells just incorporate protection against overcharging at high currents.

NiCd batteries can charge at several different rates, depending on how the cell was manufactured. The charge rate is measured based on the percentage of the amp-hour capacity the battery is fed as a steady current over the duration of the charge. Regardless of the charge speed, more energy must be supplied to the battery than its actual capacity, to account for energy loss during charging, with faster charges being more efficient. For example, the typical "overnight" charge, called a C/10 charge, is accomplished by applying 10% of the batteries total capacity for a period of 14 hours; that is, a 100Ah battery takes 140Ah of energy to charge at this rate. At the "fast charge" rate, done at 100% of the rated capacity, the battery holds roughly 80% of the charge, so a 100Ah battery takes 120Ah of energy to charge (that is, approximately 1 hour and fifteen minutes)

How the terminal voltage of a typical NiCd cell (and

also its temperature) tends to vary during charging. Both the inflection point and the voltage peak are used for end-of-charge detection in high-end chargers.

The best method of charging is the method so called delta-V method. If one plots the terminal voltage of the cell during a charge with a constant voltage, it will continue to rise slowly as charging progresses. At the point of full charge, the cell voltage will drop in a fairly short time. The amount of drop is small, about 10 mV/cell, but is distinctive. There are circuits out there built specifically to look for this. This method is expensive and tedious, but gives good reproducible results. There is a danger in this though. In a battery with a bad cell this delta - V method may not work, and one may end up destroying all the cells, so one needs to be careful. If one ends up putting in more than double the charge capacity of the cell, then something is wrong.

Another cheap way is to measure the cell temperature. The cell temperature will rise steeply as full charge is reached. When the cell temperature rises to 10 degrees C or so above ambient, stop charging, or go into trickle mode.

Whatever method one chooses, a failsafe timer is a requirement with high charge currents. Don't let more than double the cell capacity of charge current flow, just in case. (i.e. for a 800 mAh cell, no more than 1600 mAh of charge).

A lot of work done by battery researchers in recent years, has shown that NiCds

respond better to a pulsed charging waveform than to a steady DC current. By applying the charge current in one second pulses with brief ‘rest’ periods between them, the cells are better able to absorb the charge efficiently. This is particularly true at the higher charge rates used in fast chargers.

‘NiMH’ battery

The first consumer grade NiMH batteries began to appear at the end of the 1980s. Positive electrode development was done by Dr. Masahiko Oshitani from Yuasa Company, who was the first to develop high-energy paste electrode technology. The association of this high-energy electrode with high-energy hydrid alloys for the negative electrode, discovered by Philips Laboratories and French CNRS labs in the 1970s, led to the new environmentally friendly high energy NiMH battery.

The nickel-metal hydride or ‘NiMH’ battery is in many ways a development from the NiCd. The construction of most NiMH batteries is almost identical to that of NiCds.

Like NiCds the positive plate is of nickel with nickel oxide/hydroxide, and the electrolyte is potassium hydroxide. However in the NiMH battery the negative electrode is made from a hydrogen storage alloy such as lanthanium-nickel or zirconium-nickel. NiMH batteries have up to 30% higher energy storage density compared with NiCds, but still display some memory effect. They’re not as happy with deep discharge cycles, though, and tend to have a shorter working life. The self-discharge rate is also about 50% higher than NiCds.

Compared to NiCd, NiMH batteries have a higher capacity and are less toxic, but are still slightly more expensive. In addition, a NiCd battery has a lower self-discharge rate (for example, 20% per month for a NiCd, versus 30% per month for a NiMH under identical conditions).

Charging NiMH batteries

The charging voltage for NiMH batteries is in the range of 1.4-1.6 V/cell. A fully charged cell measures 1.35-1.4 V (unloaded), and supplies a nominal average 1.2 V/cell during discharge, down to about 1.0-1.1 V/cell (further discharge may cause permanent damage).

Unlike NiCds, NiMH batteries tend to dissipate heat during all of the charging process — not just following the full charge point, as with NiCds. This tends to mean that NiMH batteries can only be charged at about half the rate of NiCds, unless temperature sensing is used to limit charging current.

Broadly speaking, though, most of the charging techniques which is used for charging NiCd batteries can be used with NiMH batteries. The main difference is that although the charging voltage characteristic of a NiMH cell has the same basic

shape, the actual voltage levels are different. So chargers for NiMH cells must usually be arranged to sense the terminal voltage rate of change, and use the positive delta voltage (+DV) method of end-of-charge detection.

Many modern pulse-type chargers are designed to charge either NiCd or NiMH cells, and can automatically sense which type is present — adjusting their charging characteristic to suit.

Summary

- Do let the cells discharge to 1.0V/cell on occasion through normal use.

- Don't leave the cells on trickle charge for long times, unless voltage depression can be tolerated.

- Do protect the cells from high temperature both in charging and storage.

- Don't overcharge the cells. Use a good charging technique.

- Use correct charger type for NiCd or NiMH battery.

Remember, you CAN NOT USE charger which charge NiCd batteries for charging NiMH battery and you CAN NOT USE charger which charge NiMH batteries for charging NiCd battery. If you want to charge NiCd and NiMH batteries by one charger, use charger that supports both types.

For more information you can read following:

- Nickel-cadmium battery

- NiCd Battery FAQ V1.00

- Understanding NiCd batteries

- Using & charging NI-CAD batteries

- The Truth About NiCd Batteries

- Nickel-metal hydride battery

Footnotes

- ^ The abbreviation NiCad is a registered trademark of SAFT Corporation and should not be used to refer generically to nickel-cadmium batteries, although this brand-name is commonly used to describe all nickel-cadmium batteries. On the other hand, the abbreviation NiCd is derived from the chemical symbols of nickel (Ni) and cadmium (Cd), though it is not to be confused with a chemical formula.

Which Cordless Drill Should You Purchase?

Consumer Reports tested dozens of cordless drills and found that you don't have to pay top dollar to buy one that gets the job done. Video from KCRA Sacramento's Channel 3

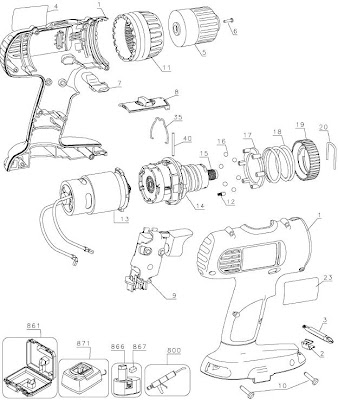

Inside the cordless drill

Main parts of cordless drill are:

- 1 - CLAMSHELL SET

- 2 - CHUCK

- 9 - DC SWITCH

- 11 - ADJUST COLLAR

- 13 - MOTOR

- 14 - TRANSMISSION/CLUTCH ASSEMBLY

- 866 - BATTERY

You can see that cordless drill is very simple tool. And now you can ask, so if cordless drills are so simple inside, why exist so much different models on the market?

And the answer is: the main difference between models consist in battery type and battery voltage, motor type, supported operations and weight. Exist and other parameters but this is key factors.

In conclusion these are the main features to remember to look for when buying a cordless drill:

- Battery type and Voltage

- Chuck Size

- Number of Speeds

- Clutch (Torque) Settings

- Weight

These words make me laugh

A WOMAN SHOULD HAVE .....

a set of screwdrivers, a cordless drill, and a black lace bra...

found here

History of drills: from bow drills to cordless drills

This blog is about cordless drills and things that are related to them. But I think that the right way to go is to give information about drills in general firstly. So I decided to give you a brief information about drills and history of drills.

Let's party started :)

About drills

The drill bit is gripped by a chuck at one end of the drill, and is pressed against the target material and rotated. The tip of the drill bit does the work of cutting into the target material, slicing off thin shavings (twist drills or auger bits) or grinding off small particles (oil drilling).

Brief history of drills

Drills come to us from date of the ancient Harappans and Egyptians.

The drill is pictured in tombs from the Third to

Twenty-sixth Dynasties. It appears frequently as a hieroglyph for either "craftsman" or "drill". Presumable cutting bits of flint have been found by the

hundreds. There are hollowed vases and blocks of stone from the Thrid Dynasty show appropriate cavities made in the course of dressing to level.

In Egypt, a number of carpentry bow-drills have been found that were used by the ancient Egyptians (Fig. 1, Petrie 1974a).

So the earliest drills was bow drills.

These drills are called "bow drills" thanks to the bow-rope by which drill bits were given in motion.

Fig 1. Ancient Egyptian bow-drill (after Wilkinson 1878).

Fig 2. Representation of the ancient Egyptian coring drill used in the rock cutting experiments of Stocks (1993, 2001)

Next drill type which is come from past to us is a gimlet.

A gimlet is a hand tool for drilling small holes, mainly in wood, without splitting. It was defined in Gwilt's Architecture (1859) as "a piece of steel of a semi-cylindrical form, hollow on one side, having a cross handle at one end and a worm or screw at the other".

A gimlet is always a small tool. A similar tool of larger size is called an auger. The cutting action of the gimlet is slightly different from an auger, however, as the end of the screw, and so the initial hole it makes, is smaller; the cutting edges pare away the wood which is moved out by the spiral sides, falling out through the entry hole. This also pulls the gimlet further into the hole as it is turned; unlike a brad awl, pressure is not required once the tip has been drawn in.

The name "gimlet" comes from the Old French guimbelet, probably a diminutive of the Old English "wimble", and the Scandinavian wammie, to bore or twist; the modern French is gibelet.

Fig 3. Gimlet.

I didn't find more information about drills in The Middle Ages so we

jump to 19 century. (If you have such information please share it with me, thanks :) )

Charles Miner, grandson of Nathan Daboll, has invented a breast-drill and self-centering brace for bits.

The brace patent book shows some eggbeater and breast drill patents among the braces, and the earliest of them is US patent #730, by George Page of Keene, New Hampshire, for a "Geared Drill Stock". This patent is dated May 8, 1838.

The text of the patent seems to indicate that his improvements for this style of tool include the adjustable length crank arm and a friction roller that

runs against the back side of the main gear to keep it running more evenly. It would seem that this type of drill preceded his patent. The patent is actually for

improvements to the style of drill, not the basic type of drill.

Fig 4. Picture from US Patent #730

The invention of the electrical drill is credited to Mr. Arthur James Arnot, in 1889, at Melbourne, Australia.

Wilhelm Fein invented the portable electric drill in 1895, at Stuttgart, Germany.

In 1917, Black & Decker patented a trigger-like switch mounted on a pistol-grip handle.

For now that's all.This post is still draft and I'll post more information about history of drills in future.

Links and References

About Drills

Ancient Egyptian Stoneworking Tools and Methods: Stone vase making

Ancient Egyptian Stoneworking Tools and Methods: Copper coring drills

Gimlet (tool)

The Egyptian Drill and the Origin of the Crank Richard S. Hartenberg, John Schmidt, r. Technology and Culture, Vol. 10, No. 2 (Apr., 1969), pp. 155-165

OldTools Archive

US Patent #730

All-Blogs.net directory